Authors: Ziad Abu El-Rub, Rajwa Abu Hassan, Rami Alnajjar and Malek Alkasrawi

DOI: https://doi.org/10.48103/jjeci592022

JORDANIAN JOURNAL OF ENGINEERING AND CHEMICAL INDUSTRIES (JJECI)

Pages: 71-77

Abstract

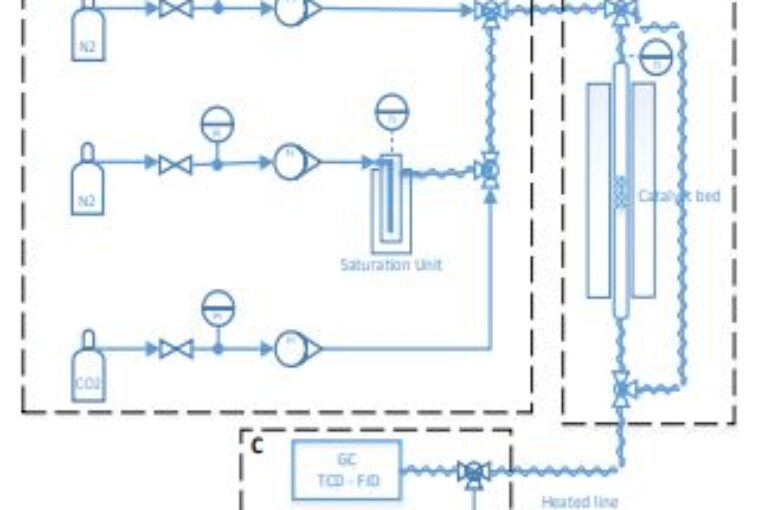

This study aims to develop a kinetic model for natural kaolinite as a potential tar removal catalyst in biomass gasification processes. The catalyst was crushed, sieved (0.2mm), and analyzed using TGA, BET, and XRF. The apparent first-order kinetic parameters of the dry reforming reaction at temperatures ranging from 750 to 900°C under 1atm were used to determine kaolinite’s catalytic

activity. It was found that both dry reforming and thermal cracking reactions occurred simultaneously. Furthermore, the raw kaolinite catalyst significantly removed toluene (80% at 900°C), at activation energy and frequency factor of 209 kJ/mol and 5.86×109s−1,

respectively. Capitalizing on its catalytic activity in its natural form and its high efficacy as fluidized bed material, kaolinite can have great potential in primary and secondary tar reduction measures.

Paper type: Research paper

Keywords: Toluene, dry reforming, kaolinite, catalyst, tar, biomass, gasification.

Citation: Abu El-Rub, Z., R., Abu Hassan, R., Alnajjar, and M. Alkasrawi “Kinetics of Natural Kaolinite as a Catalyst for Toluene Dry Reforming” Jordanian

Journal of Engineering and Chemical Industries, Vol. 5, No.3, pp:71-77 (2022).