Authors: Nadeen Alsmadi , Mamdouh Allawzi , Munther Kandah , Mohammad Al-Harahsheh, Salaheddin AbuYahya

DOI: https://doi.org/10.48103/jjeci7112024

JORDANIAN JOURNAL OF ENGINEERING AND CHEMICAL INDUSTRIES (JJECI)

Pages: 82-93

`

Abstract

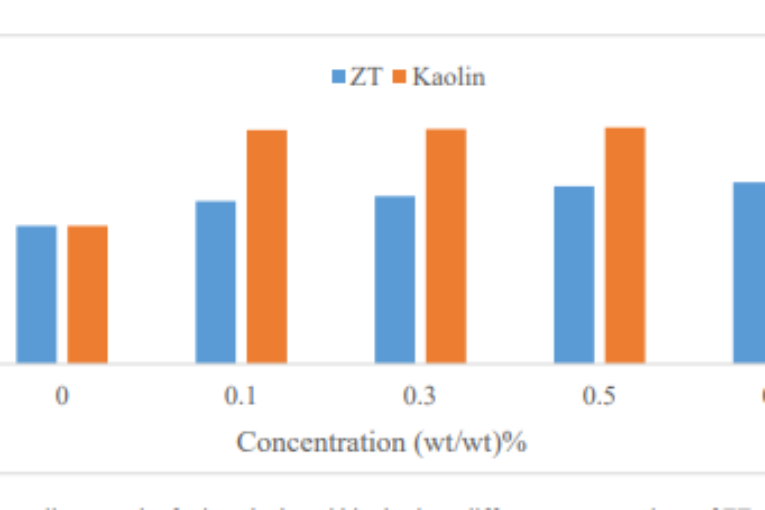

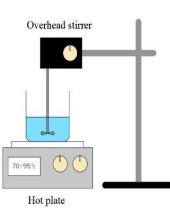

The study investigates the production of biodegradable plastic films using gelatin as a biopolymer, glycerol as a plasticizer, and natural fillers (Jordanian zeolitic tuff and kaolin) via solution casting method. Key findings demonstrate that incorporating these fillers enhances the films' mechanical properties, biodegradability, and ductility. Increased filler

concentration improves film thickness, density, tensile strength (up to 4.97 MPa with kaolin), and toughness while reducing moisture content, solubility, and elongation at break. Biodegradation tests reveal significant weight loss over time, indicating the films' potential for rapid environmental breakdown. The ductility of the films decreases with increasing

filler concentration, suggesting enhanced rigidity. These results highlight the potential of utilizing Jordanian natural resources to develop eco-friendly bioplastics with applications in packaging, soil additives, and other industries.

Paper type: Research paper

Key words: biodegradation, bioplastic, waste kaolin, zeolitic tuff

Citation: Alsmadi, N.,Allawzi, M., Kandah, M., Al-Harahsheh, M.,and S., AbuYahya, “Bioplastic Production Utilizing Jordanian Zeolite and Kaolin”, Jordanian Journal of Engineering and Chemical Industries,

Vol. 7, No.3, pp: 82-93 (2024).