Authors: Maha Mohammad AL-Rajabi, Kang Jia En, Safa Senan Mahmod, Muhammad Faiq Abdullah

DOI: https://doi.org/10.48103/jjeci7122024

JORDANIAN JOURNAL OF ENGINEERING AND CHEMICAL INDUSTRIES (JJECI)

Pages: 94-102

`

Abstract

Rice straw is an abundant agricultural byproduct with great potential as a sustainable source of cellulose. This study investigates the effect of sodium hydroxide concentration on the extraction of cellulose from rice straw through alkali delignification. Sodium hydroxide concentrations ranging from 3% to 11% were applied at a constant temperature of 60 °C for 60 minutes. The objective was to assess the impact of alkali concentration on cellulose yield and structural properties. Results showed that increasing alkali

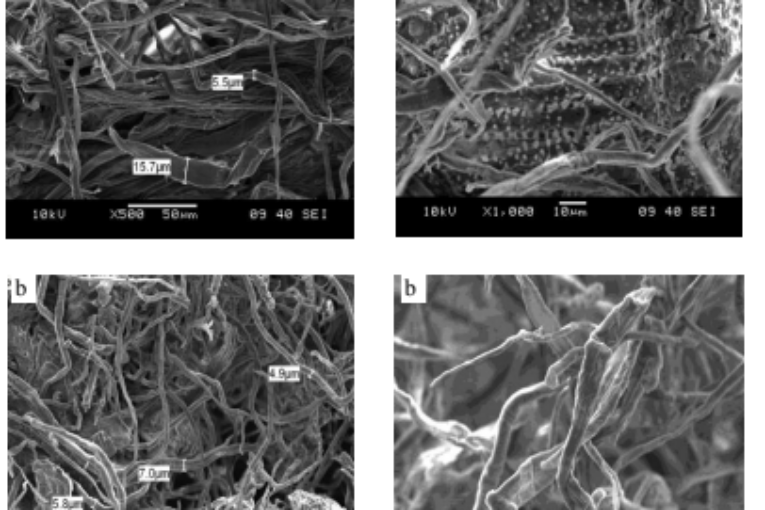

concentration led to a reduction in cellulose yield. Fourier Transform Infrared Spectroscopy (FTIR) and Scanning Electron Microscopy (SEM) confirmed the effective removal of lignin, hemicellulose, and impurities across all concentrations. Additionally, the crystallinity index (CI) increased from 47.85% to 51.37% as alkali concentration rose, indicating successful delignification. However, a balance must be considered, as lower alkali concentrations, while environmentally friendlier and yielding more

cellulose, resulted in lower purity, with FTIR, SEM, and XRD analyses revealing residual impurities in the extracted cellulose. This eco-friendly process offers a promising method for converting agricultural waste into valuable cellulose, contributing to sustainable industrial practices.

Paper type: Research paper

Keywords: Cellulose, extraction, alkali delignification,rice straw.

Citation: AL-Rajabi, M, En, K , Mahmod, S and M, Abdullah “Impact of Alkali Concentration in Delignification Treatment for Cellulose Extraction from Rice Straw ”, Jordanian Journal of Engineering and Chemical Industries,

Vol. 7, No.3, pp: 94-102 (2024).